Press Release

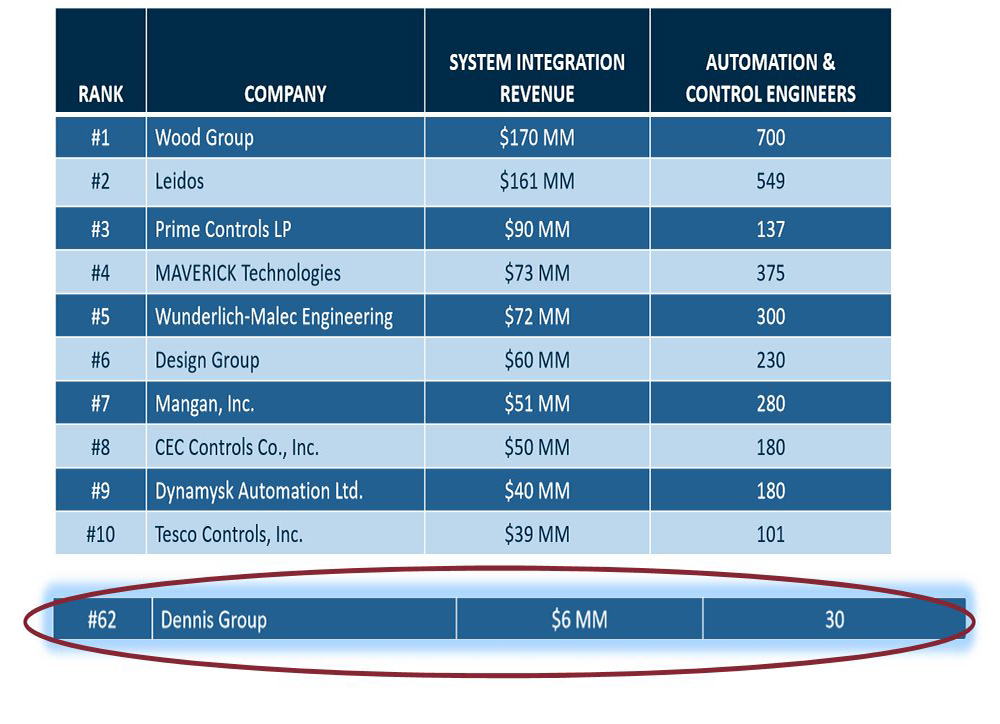

Dennis Group improved its year-over-year rank from #74 to #62 in Control Engineering’s 2016 System Integrator Giants listing. The System Integrator Giants program (SI Giants) lists the top 100 integrators by self-reported total system integration revenue.

There continues to be growth, consolidation and change in the system integration industry, and challenges faced this past year include economic turmoil, political confusion and a seismic shift in the world oil prices.

Control Engineering’s System Integrator Giants issue also featured interviews with industry leaders who discussed their views on key issues, including the Industrial Internet of Things (IIoT). David Ziskind was prominently featured and below are some excerpts.

As 2017 nears, what’s next for manufacturing?

“The forecast for manufacturing in the United States differs sector to sector with some export markets being hurt by a strong dollar, but the overall outlook for 2017 is strong. In growing sectors, manufacturers are adding capacity. Across the board, there is a continued focus on efficiency gains and most companies are authorizing capital spending for these types of projects.”

Right now, the system integration business continues to grow in importance to manufacturers looking to upgrade their plant operation. Assess the state of the system integration industry as a whole.

“System integration is critical to any manufacturing process, and the field will continue to grow in importance as more new systems are developed and deployed. Ensuring interoperability and end-to-end performance between legacy systems and new devices will be an ongoing need as manufacturers upgrade and optimize their operations. One of the biggest challenges for the system integration industry will be finding and developing enough experienced and talented individuals to support this increasing demand.”

The Industrial Internet of Things (IIoT) is an important strategy for manufacturers. What are your customers asking you about IIoT, and how are you reaching out to them with information?

“IIoT has been a hot topic among systems integrators for several years now, but the actual adoption and usage among manufacturers has been slow. While most clients are generally aware of IIoT, we have received very few inquiries. As with any new application or paradigm shift, early adopters will navigate and address the initial challenges and then the pace of adoption will grow exponentially.”

How quickly do you see IIoT being adopted in manufacturing? How quickly should it be adopted?

“While IIoT has the potential to offer wide ranging benefits from quality control to supply chain efficiency to sustainable practices, most manufacturers won’t pursue an all-in approach which would require significant capital investment to replace all of the sensors and controllers that aren’t network-enabled. Additionally, it is going to take time to overcome significant security concerns of exposing plant floor devices to the network. And IIoT adoption goes far beyond hardware/software changes — it requires significant modifications in the processes themselves. For all of these reasons, IIoT will be phased in slowly and in very specific applications. Most manufacturers will need to demonstrate the benefits of a specific IIoT application in a limited scope to help demonstrate a return on investment and alleviate their concerns before they embrace it on a broader scale.”

How can system integrators help with Industrial Internet of Things (IIoT) adoption?

“System integrators must always start by assessing a client’s needs and concerns to ensure that the company’s goals are aligned with the solution being presented. Depending upon a client’s goals, this may or may not include IIoT. However, if IIoT is deemed an appropriate option, system integrators must be able to articulate the associated risks and benefits to a client and help demonstrate the value IIoT can provide.”